Shark KGH R63

Description

We present the Shark KGH R63 hydraulic shears for cutting end-of-life tires from mining vehicles.

The shears are designed for high-volume processing of tires ranging from R22.5 to 59/80R63.

For reference, the 59/80R63 tire is the largest in the world! Nothing larger exists. Such a tire weighs 5465 kg, stands over 4 meters tall, and has a tread width of 1.5 meters. These tires are used on the largest mining dump trucks like the BelAZ 75710, with a load capacity exceeding 450 tons.

The Shark KGH R63 unit is ideal for coal and ore mines, enabling on-site recycling of oversized tires and reducing transportation costs to disposal sites. When paired with the Auto Tire Recycling KING line, it also produces rubber crumb as a byproduct.

The chunks of oversized tires produced after cutting have high bulk density and are suitable for pyrolysis processing.

Technical specifications

The unit is designed for cutting extra-large tires into chips. It can process any tire with bead seat diameters from R22.5 to R63, outer diameters up to 4028 mm, and section widths up to 1500 mm.

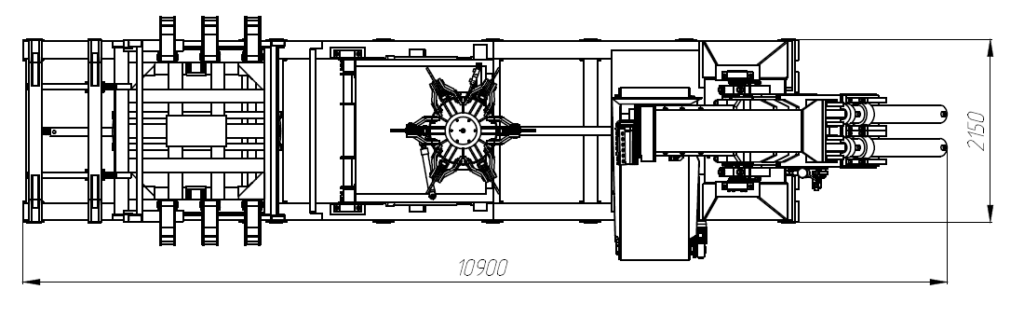

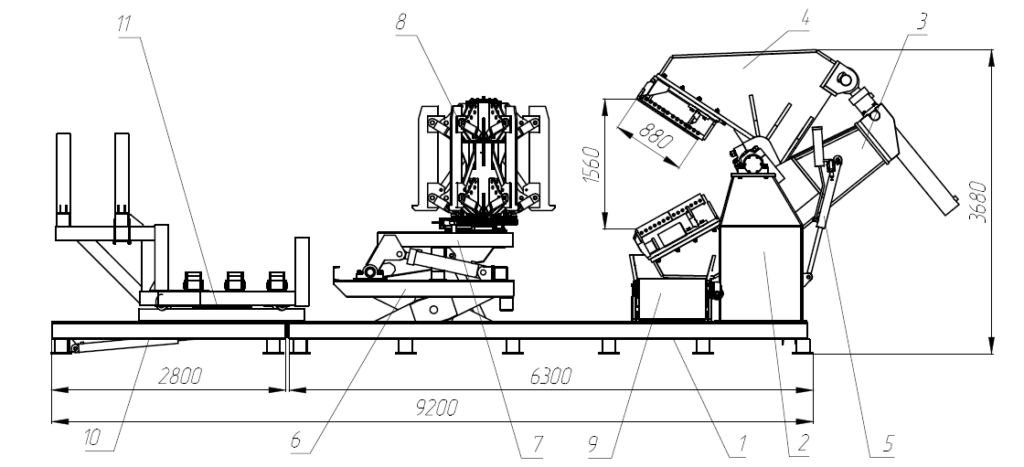

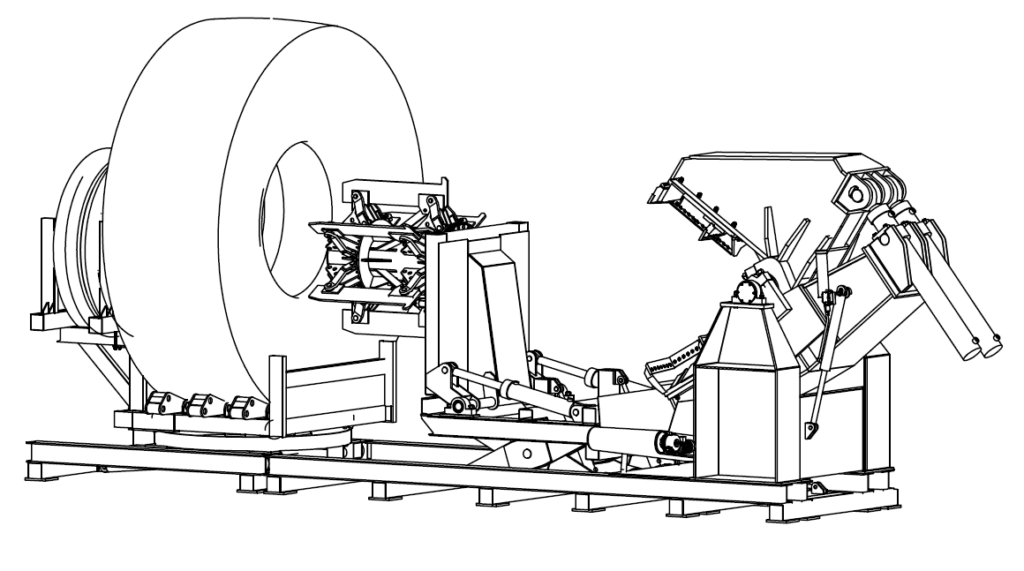

Pic 1. General view of the unit

| 1. | Shear frame |

| 2. |

Blade holder |

| 3. |

Lower blade |

| 4. |

Upper blade |

| 5. |

Stop |

| 6. |

Lifting platform |

| 7. |

Rotating platform |

| 8. |

Hub |

| 9. |

Conveyor |

| 10. |

Reloader frame |

| 11. |

Reloader platform |

Universal hub adjustable to any bead seat diameter. Features automatic clamping under the tire’s own weight.

The rotating platform turns the hub with the tire around the hub axis and can also rotate the hub 90° to a horizontal position.

The lifting platform raises and lowers the hub and moves it along the unit frame.

The reloader enables quick and convenient tire loading. Its platform rotates 180° and has two cassettes: one for the tire and one for bead ring remnants. The platform can also move along the unit axis.

Unit Operation

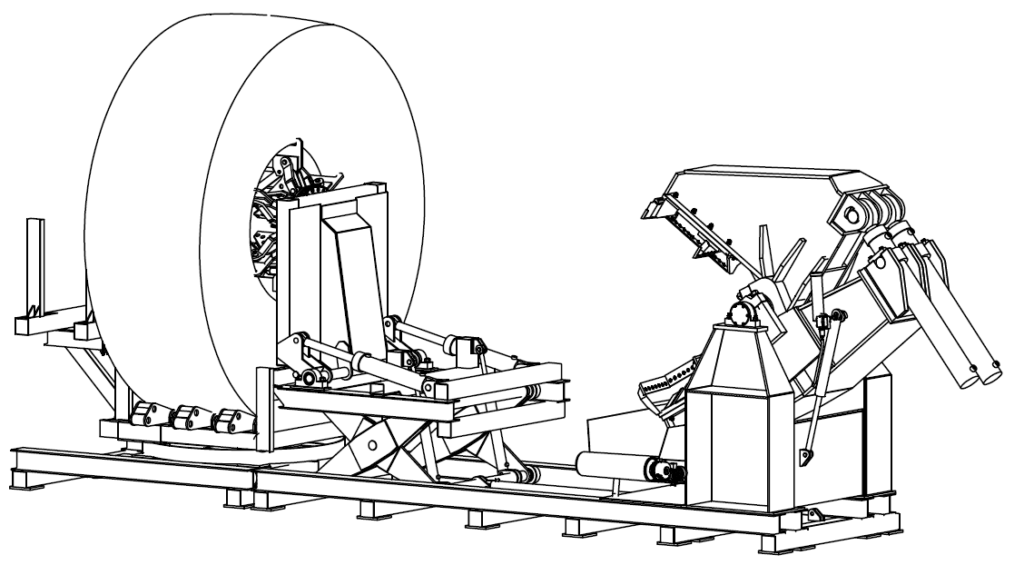

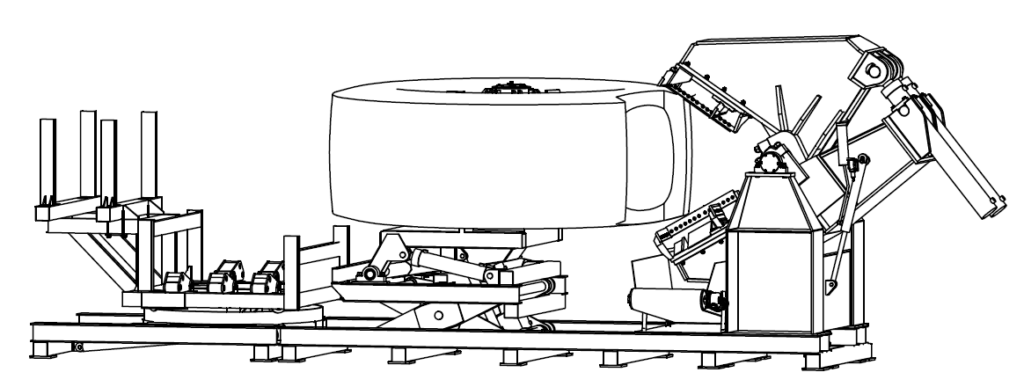

The tire is positioned on the reloader using a forklift. The tire is mounted onto the hub, which is in a horizontal position. The tire is loaded into the unit by raising the platform and rotating the hub to a vertical position.

The tire cutting process into chips is then carried out similarly to the «Shark KGH» unit.

To reduce the size of the chips, additional adjustable transverse blades are installed on the upper and lower blades, which cut the tread into two parts at the bend.

After the tire cutting is completed, the remaining bead rings are unloaded into the reloader cassette. The platform rotates, moving the hub with the bead rings to a horizontal position. The bead rings are lowered into the reloader cassette. The unit platform moves away, and the reloader platform rotates 180°.

The tire cutting process repeats. During the cutting of the tire, the loader transports the bead rings to the storage or processing area, brings the next tire, and loads it into the reloader cassette. This minimizes the time spent on auxiliary operations, ensuring a continuous tire cutting process.

Video showing the full processing cycle of a 59/80/R63 mining dump truck tire—the largest tire in the world!

Request for Commercial Proposal

To receive a commercial proposal for the Shark KGH R63 oversized tire cutting shears, we recommend contacting any of our specialists in the relevant section. You can also submit an equipment inquiry using any of the feedback forms available on the website.

The commercial proposal includes: equipment price, process description, and technical specifications.

If you have additional questions, suggestions, or require specialist consultation,

Call our toll-free hotline: 8 (950) 009-04-12.

Мы используем cookie-файлы для улучшения предоставляемых услуг. Продолжая навигацию по сайту, вы соглашаетесь с правилами использования cookie-файлов.